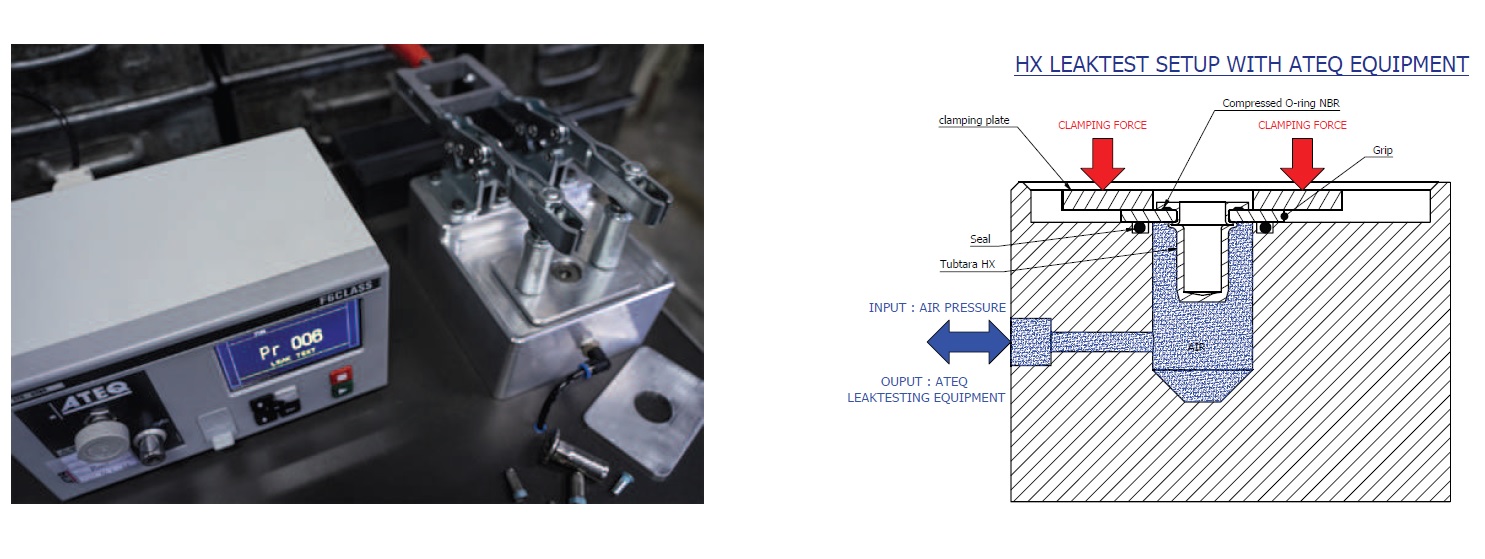

Together with ATEQ we developed a reliable test method for our watertight blind rivet nuts. We designed a housing, in which a test plate with an installed sealed rivet nut (no torque applied), is mounted and tightly clamped. The housing is connected to leak-detection equipment, generating a dedicated air pressure during a certain amount of time and for a specific part volume. Any decrease in pressure, however small, will be detected and compared to predefined parameters, which are calculated and correlated to verify that the rivet nut-plate assembly is in fact leaktight.

Following IEC 60529, an IPx7 classification means immersion for up to 30min. at a depth between 15 – 100cm. 1m water column = 100mbar, at DEJOND we test at 200mbar.

With the ATEQ leak testing equipment we measure a pressure drop ΔP in Pa, which can be converted into a leak (cm³/min. or ml/min.) where air is allowed to pass through an opening but no water yet, until the surface tension of water is broken. The pressure drop threshold determination is a confidential ATEQ algorithm.