Recommended tightening torque values (Nm)

Max. recommended torque to avoid damaging the threaded connection and ensure optimal

screw-nut assembly:

| M3 | M4 | M5 | M6 | M8 | M10 | M12 | |

| Aluminium | 2 | 2,2 | 4,5 | 9,5 | 17 | 30 | |

| Steel | 2,5 | 3 | 5,9 | 11 | 25 | 49 | 80 |

| Stainless Steel | 2,5 | 3 | 5,9 | 11 | 25 | 49 | 80 |

Recommendations for 8.8 bolts in steel and class A2-70 bolts in stainless steel.

Mechanical properties - How do we test them?

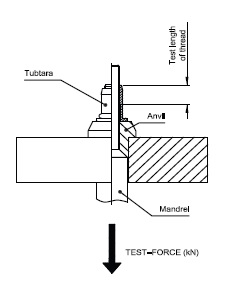

| PULL-OUT (thread strength) Determines the force (kN) required to destroy (pull out) the threads of the Tubtara® blind rivet nut, by pulling a screwed-in mandrel towards the headof the Tubtara®. In many cases the mandrel will break before the threads would fail (see “>” in mechanical values table) The strength towards the opposite direction is ± 1/3 of the pull out strength. PROOF LOAD test according to ISO 898-2 possible (on request). |

|

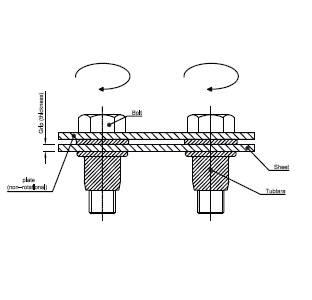

| Determines the maximum torque (Nm) that the Tubtara® can resist.The Tubtaras are installed in a bolted assembly, using a non-rotational plate. In most cases the bolt will break before the threads would fail. (see “>” in mechanical values table). |

|

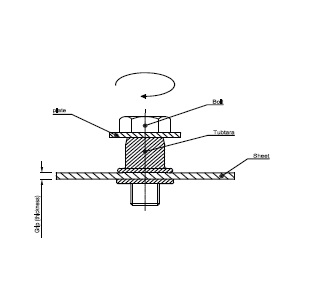

| TORQUE-TO-TURN (spin out) Determines at which couple (Nm) the Tubtara® starts to rotate (spin) in the parent material in which it is installed. Tested from the blind side with a tightened bolt and a washer. In an assembly, required torque-to-turn force will be higher, due to increased clamping pressure and friction resistance after tightening the assembled bolt. In some cases the bolt will break before the threads would fail. (see “>” in mechanical values table). |

|

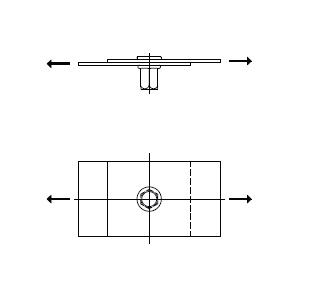

| SHEAR TEST Tests the strength (kN) of an installed Tubtara® (without assembled bolt) towards shearing. In many cases the Tubtara® will be pulled out of the plate without shearing, or shear in the middle between the 2 plates. Plate material, hardness and how holes are formed (drilled, punched or laser cut) will influence test results. |

|