HX/KX Tubtara® with O-ring seal under the head.

| Information about NBR O-Ring & compatibility with other products | |||||||

| Shore Hardness | 70 | Aromatic Hydrocarbons |

x | Lye | x | ||

| Hydraulic fluids | xxxx | Aliphatic Hydrocarbons |

xxx | Chlorinated Hydrocarbons |

x | ||

| Fuel Oils | xx | Water under 80°C | xxx | Ozone & Sunlight | x | ||

| Organic Oils | xxxx | Water over 80°C | x | Temperature range °C | -30 +120 | ||

| Brake Fluid | - | Alcohols | xx | Electr. properties | - | ||

| Silicone & Grease | xx | Ketone | - | Compression sets | xxx | ||

| Gasoline | xxx | Acid (concentrated) | - | Flame resistance | No | ||

| Aromatic fluids up to 50 % | xx | Acid (diluted) | x | Kerosene | xxx | ||

Key: xxxx very good - -> x satisfactory - not suitable.

Seals in other materials like EPDM on request. Store in a dry and dark place (all boxes are marked)

(H)DPX/HDKX Tubtara® with applied (chemical) seal under the head.

Several seal options are possible for our (H)DPX and HDKX series, depending on head shape and application requirements. For P (flat head) parts, we advise precote® 200 or Rimlex® 620B, or Rimlex® 310 for high temperature applications.

Our HDKX series with low profile head, feature a thin precote® 5 or 15 acrylate seal, but note that these require specific hole preparation to obtain a leakproof assembly (see below).

These seals are resistant to many automotive oils, antifreeze and transmission fluids, and ensure a leakproof assembly, if correctly installed. Technical data sheets are available on request.

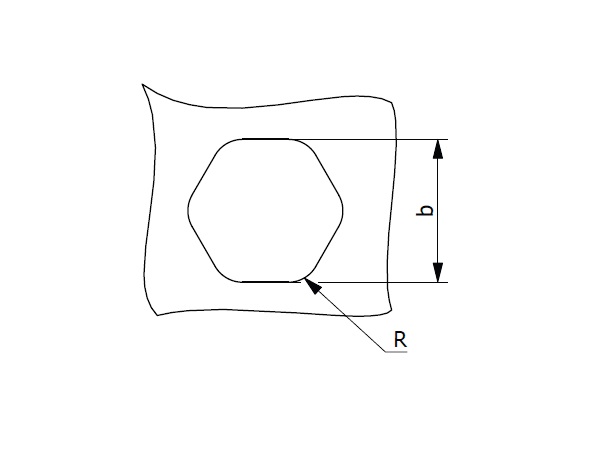

Hole preparation for semi-hex HDKX + Precote® seal.

To obtain an IP x7 leakproof assembly with semi-hex (stainless steel) HDKX series, the hexagonal holes need to be formed with a radius:

|

Radius hexagonal hole |  |

||

| THREAD | b+0,1 | R+/-0,05 | ||

| M4 | 6,0 | 1,6 | ||

| M5 | 7,0 | 1,8 | ||

| M6 | 9,0 | 2,2 | ||

| M8 | 11,0 | 2,7 | ||

| M10 | 13,0 | 2,8 | ||

| INFORMACJE TECHNICZNE |